Megnajet’s fluid management systems power Cyan Tec’s bespoke automation solutions

Cyan Tec, a UK-based specialist in automated laser and inkjet machinery is utilising Megnajet’s fluid management systems to enhance the performance, flexibility and reliability of its inkjet solutions.

With expertise in automation and precision engineering, Cyan Tec designs and manufactures high-tech, bespoke machines for complex industrial applications across key sectors – including automotive, aerospace, nuclear, medical and consumer products. In these demanding production environments, accurate fluid control is critical and Megnajet has been ensuring optimal performance of Cyan Tec’s advanced inkjet machines since 2017.

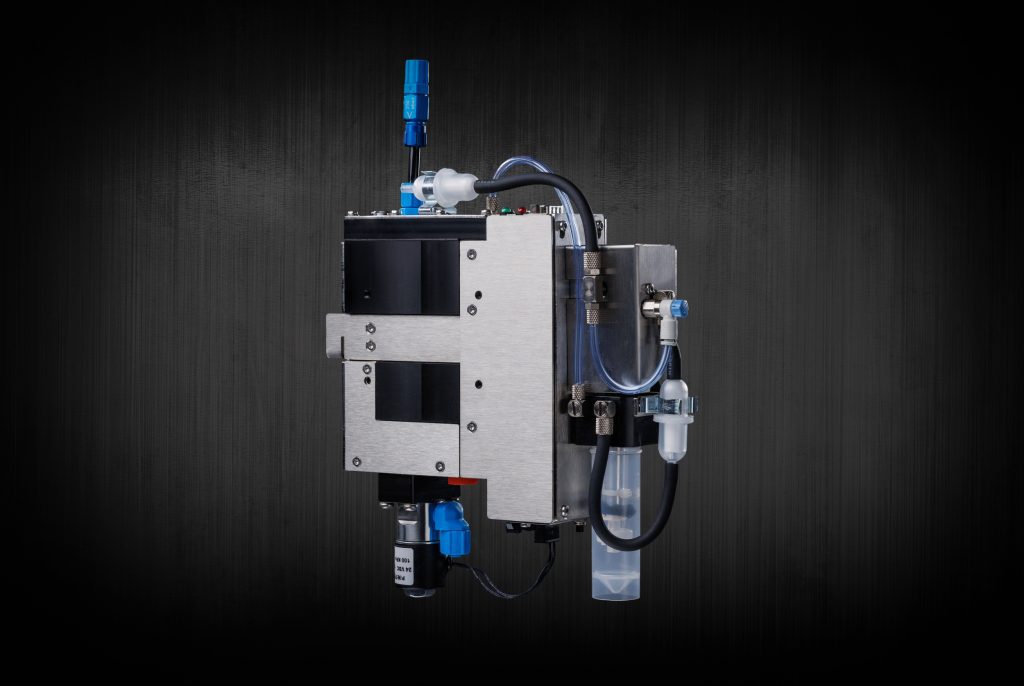

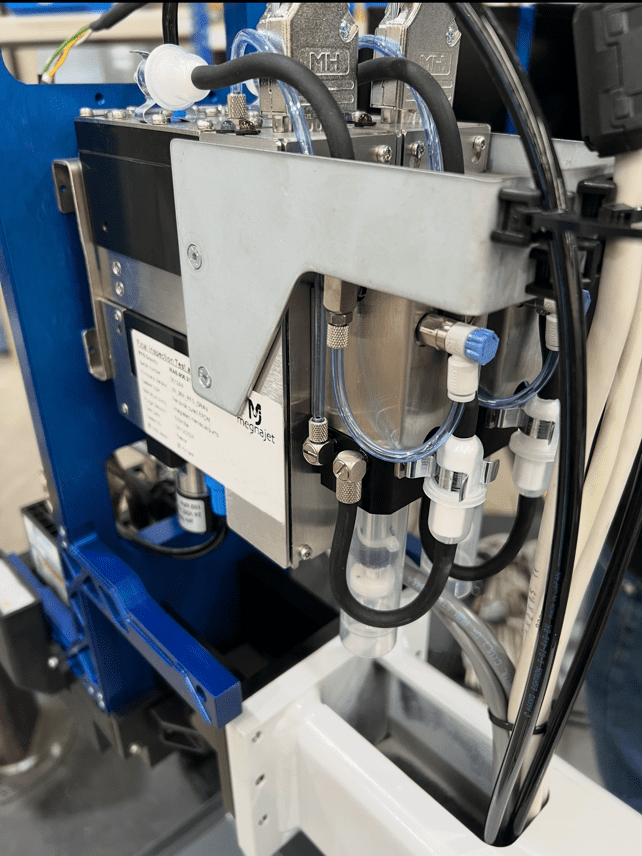

The partnership has seen a wide range of Megnajet’s fluid management system families integrated by Cyan Tec to provide the control of meniscus pressure, temperature and recirculation rates required to ensure consistent fluid delivery.

Chosen for their printhead compatibility, Megnajet’s systems allow Cyan Tec to choose the most suitable ones for each application. This versatility is crucial in developing its complex, high-tech machines tailored to exact customer requirements.

In a recent project for a newly launched consumer product, five Megnajet fluid management systems are powering Cyan Tec’s bespoke robotic machines. The Megnajet RackFit LFR (PV) and Gravity systems were chosen for their compact design, versatility and the reliable recirculation required for this innovative 360-degree robotics project.

Grant Copson, Project Manager at Cyan Tec commented: “Megnajet has been a trusted partner for many years, providing high-quality fluid management systems that integrate seamlessly into our machines.

“Their technology offers the precision and reliability our customers demand while giving us the flexibility to choose the right printheads for each application. This versatility is key to developing our highly specialised inkjet solutions, and Megnajet’s responsive support team helps us maintain efficiency with minimal downtime.”

Mike Seal, General Manager at Megnajet, added: “Cyan Tec’s expertise in industrial inkjet automation demonstrates the importance of highly accurate and adaptable fluid management. Flexibility, precision and reliability are central to our products – all of which are essential to Cyan Tec’s machinery. We’re proud to play a part in driving their advancements and look forward to continuing this strong partnership.”

As demand for automation and industrial inkjet technology continues to grow, Cyan Tec remains committed to integrating the most advanced and adaptable components into its solutions. Megnajet’s fluid management systems provide the consistency, performance and versatility needed to support Cyan Tec’s next-generation printing technologies.

More from Megnajet on Eye on Display.