From concrete on a roll to stunning murals, light displays and more. Jack visited 2601 Creative Print to find out more.

2601 Creative Print in Bristol has recently renovated its new premises to showcase the broad range of products and services it offers. It houses a business built on creativity, strong relationships, and a strategic investment in technology designed to deliver exceptional displays for exceptional clients.

The company was born from a perfect partnership of a printer and a designer. “My background was print, while Steve’s [Williamson] was design,” explains co-founder Paul Johnson. “We wanted to be a bit different. We do a lot of work for TV and film, which demands high quality and fast turnarounds. But this is what we love. Anything creative, anything unusual, we get excited, and once we get excited, we just go with it.”

This philosophy has guided the company for over 10 years, helping them carve out a niche in a competitive market. Instead of chasing high-volume, low-margin work, 2601 has focused on becoming a trusted partner for clients who demand something special. “We don’t want to just do banners; we don’t want to print just flags or stickers because we found that the online world just swallows it up. We want to thrive on premium projects where someone has a proper budget and we can get creative with it,” he says.

A showroom to inspire

Three years ago, 2601 moved into a new building, which was an empty shell with a single plug socket. Today, it is a stunning showcase of what is possible with modern print and finishing. “This is one of the reasons why we’ve made it the way that we have. The main objective was to get to a stage where we can invite people in and show them everything that we do. There is no better way to present our capabilities than showing exactly what we can do.”

Innovation in materials

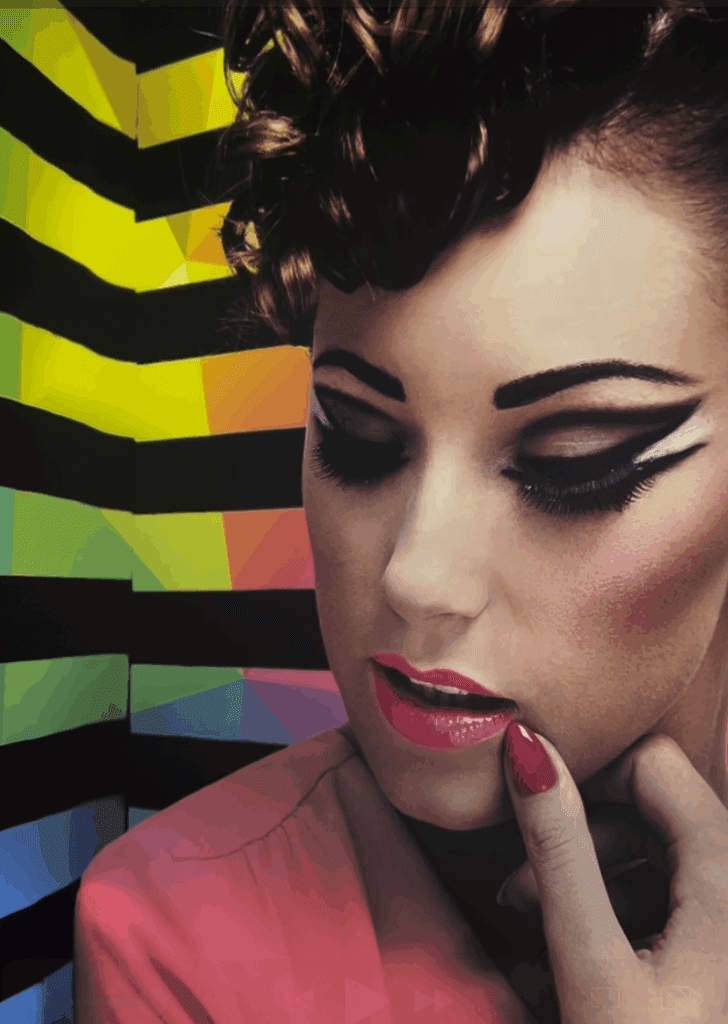

From the moment you walk in, the space is a living portfolio. The stairs are wrapped in the remarkable X-Stone concrete-on-a-roll material, the meeting room features a ‘day and night’ backlit fabric graphic that transforms from a black and white image to full colour, and the offices are a masterclass in acoustic design.

X-Stone concrete material is an incredibly innovative product that 2601 has sourced. “It’s recycled concrete dust from a quarry that gets mixed with a special flexible glue,” Paul explains. “It’s then rendered onto a Hessian backing sheet, and a mould comes down and presses onto it, which creates the textures.”

The material can be coloured to achieve a rust or travertine effect, or even a custom brand colour. It’s a specialist installation, applied with a high-tack paste and a filler paste for the joints, but the result is a stunning, authentic finish that has become a signature feature in many of 2601’s interior projects.

Paul also describes the process behind the unique day/night backlit effect in the main meeting room. “It’s a fabric on which we have layered the inks up. We printed it full colour, then we flooded it with white, and then we printed it full colour again. When LED lights penetrate through the back, it pushes all the colour through the black and white image on the front. So when you turn the lights on, it all goes colour.” He adds that while it’s popular for TV and film backdrops, it also has huge potential for creating dynamic displays in offices and reception areas, with programmable LEDs allowing for effects like a timed sunrise and sunset.

Technology for purpose

To deliver these ambitious projects, 2601 has invested heavily in a diverse range of equipment, strategically splitting its workflow across two floors. The upstairs finishing department houses HP Latex machines, chosen for their eco-friendly, flexible inks, alongside a Rolls-Roller mounting bed and a dedicated electrics and wiring station for bespoke illuminated projects.

Downstairs is home to the larger format technology. A key move for the business was splitting their old hybrid machine into two separate, dedicated units: a Mimaki flatbed and a 3.2m Mimaki UJV55 roll-to-roll. “It’s the best thing we’ve done really, to split the machine into two, because it’s just helped separate the workflow,” Paul explains. The UJV55 has become a workhorse, running day and night on everything from one-piece wallpapers to fabrics.

The latest investments include a high-speed Jetrix flatbed printer, chosen for its ability to handle oversized sheets for printing on concrete and 2.8m acoustic panels. This is complemented by two different finishing tables—a Summa and a J-WEI cutter. “The Summa is for the clean stuff—banners, stickers, vinyls,” Paul says. “The J-WEI is a bit more industrial. It’s got a better router and does all our V-grooving on the acoustic panelling. It’s a manlier machine.”

This diverse toolkit and rapid responsiveness are essential for serving 2601 Creative Print’s core market. Paul concludes, “Responsiveness to clients is key for us, especially with TV and film. If they’re filming that day, that night, that evening, they have to have it right away. We win projects and are working on projects before other companies have even quoted. It’s the strength of our client relationships that is most key for us.”