Portsmouth-based Sticker Wizard has invested in a range of Roland DG print and cut technologies including the VersaUV LEC2-330 and TrueVIS VG3

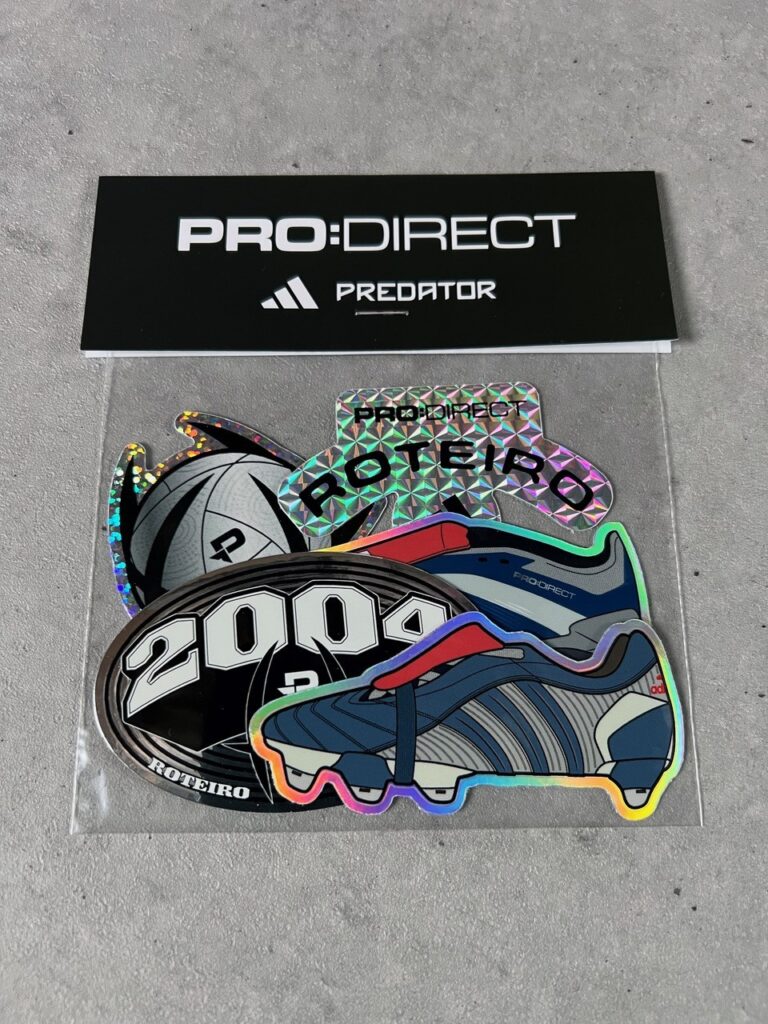

The COVID-19 pandemic reshaped the UK business landscape, sparking a surge in entrepreneurship. Against this backdrop, Sticker Wizard, founded in Portsmouth by print professional Chris Jamieson, emerged as a success story. The company has evolved from a one-man bedroom operation into a trusted supplier for global brands including Nike, Adidas, TikTok, and Marc Jacobs. At the centre of this growth is a commitment to creativity, quality, and quick turnaround, utilising Roland DG print technology.

Mr Jamieson’s journey with Roland DG began when he first used a Roland DG printer at a signage company. During lockdown, he launched Sticker Wizard as a side project, initially investing in the Roland DG VersaSTUDIO BN-20 desktop printer/cutter to produce small runs of stickers.

“I started making simple designs based on cultural moments, and they just took off,” Mr Jamieson recalls. “The BN-20 was brilliant to start with, but I quickly realised I needed something bigger and faster. The VS-300i gave me that flexibility.”

As Sticker Wizard grew, Mr Jamieson invested in the Roland DG VersaCAMM VS-300i, a 30-inch printer/cutter. He explains that the VS-300i was a “real step up” which allowed him to take on more complex briefs and deliver them at the quality and speed clients expected.

Expanding Capabilities with UV Printing

As Sticker Wizard’s client list grew, the demand for unique materials and finishes increased. To meet this demand, Mr Jamieson invested in the Roland DG VersaUV LEC2-330 UV printer/cutter.

“Anything quirky – chrome, fluorescent, specialty vinyl – goes straight through the UV printer,” Mr Jamieson explains. “It gives me confidence that no matter how demanding the brief, I can reproduce colours and finishes exactly as clients expect.”

Mr Jamieson notes that the LEC2’s UV technology reflects a trend towards sustainability and waste reduction. By allowing direct printing on diverse substrates and eliminating the need for additional processes, he minimises waste while expanding his creative offering.

To handle larger orders and speed up production, Mr Jamieson recently added a Roland DG TrueVIS VG3 large-format printer/cutter. The VG3 delivered the speed, width, and unattended production capability needed to fulfil bulk orders.

Software and Support

For Mr Jamieson, Roland DG’s printers are only half the story. The other half lies in the software and support ecosystem. “I’ve used VersaWorks from the very beginning, and it just works,” he says. The latest VersaWorks 7 RIP software supports advanced features such as variable data printing, five print queues, and direct access to Roland DG’s Colour System and PANTONE libraries. These tools are essential for the precise reproduction of brand colours.

Mr Jamieson also credits Roland DG’s reliable hardware support and training resources as a key factor in his decision to continue with the brand.

Looking ahead, Mr Jamieson plans to consolidate his Roland DG fleet into a larger commercial space. Future investment plans include an up-specced Roland DG LG-540 UV twin-head printer, which will further accelerate UV production capacity. Mr Jamieson expects the LG-540, with its high-resolution print quality up to 1,440 dpi and EUV5 inks, to further accelerate UV production and give him “even more flexibility”.

Mr Jamieson concludes, “Roland DG has been with me every step of the way, from my first BN-20 to large-format UV and TrueVIS solutions. They will continue powering my growth.”