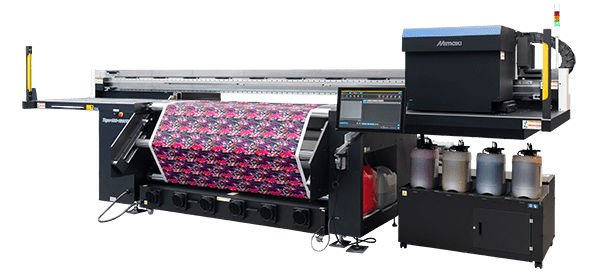

The Mimaki Tiger600-1800TS is a high-speed industrial dye-sublimation printer designed for large-scale textile production. With a maximum media width of 1900 mm and a printing width of 1850 mm, it is engineered for exceptional productivity, achieving a top speed of 550 m²/h. This significant speed increase over previous models is due to advanced technology, including new-generation printheads. The printer is designed for high-quality output, using MLSb510 inks that are OEKO-TEX® and bluesign® approved, meeting environmental standards for sustainable businesses.

The Mimaki Tiger600-1800TS features 8 printheads in a staggered layout, allowing for high-quality printing at high speeds. It incorporates a range of technologies for stable and continuous operation, such as Mimaki’s Nozzle Recovery System (NRS) and an advanced paper transport mechanism with a new wrinkle-removing roller, which ensures stable printing even on thin transfer paper. The printer has a compact and space-saving design, with both the paper feeding and take-up systems located at the back, reducing its operational footprint. For high-volume production, it uses a 10kg bulk ink system with a 2L buffer tank, which minimizes ink waste and allows for seamless changes without interrupting printing. The machine is supplied with Mimaki’s TxLink4 RIP software.