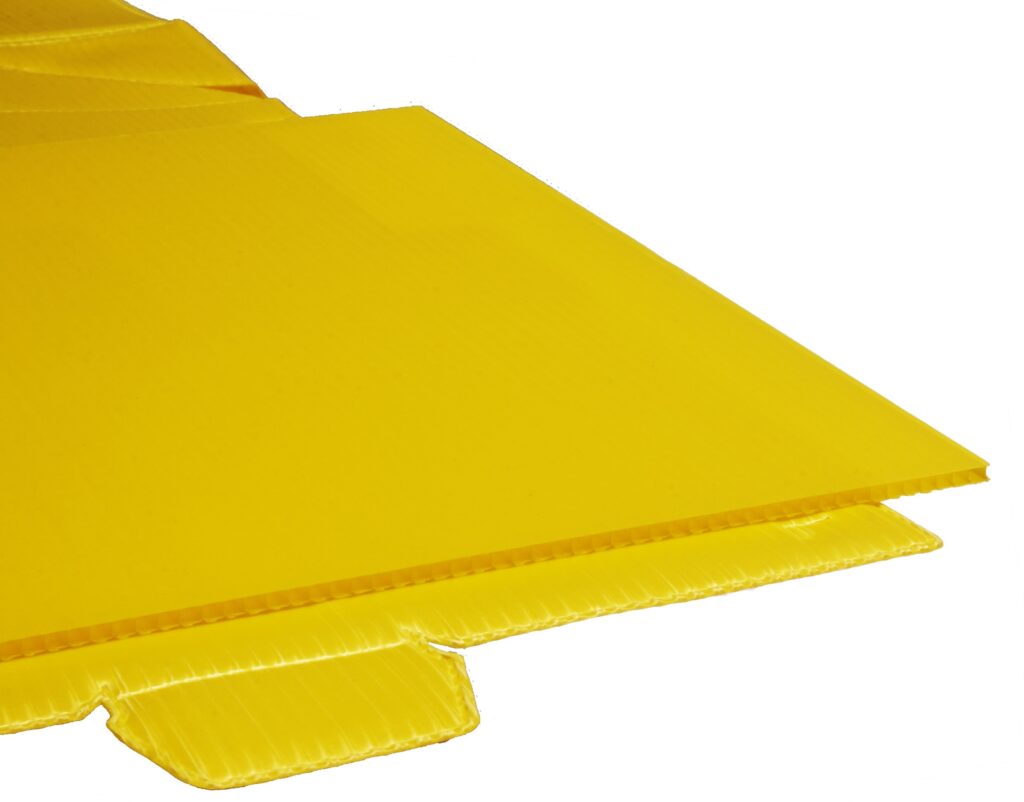

AkyPak® closed edge innovation delivers a hygienic, robust, and sustainable packaging solution

Corplex, the only manufacturer of Correx, has launched closed edge technology, the latest innovation to increase safety and hygiene use, alongside its longstanding durability and sustainability benefits.

AkyPak® is a range of reusable protective plastic packaging solutions made from Correx®, tailored to meet the needs for high-demand industries. The new technology closes the corrugated edges, protecting against common issues like contamination, tearing, delamination and significantly extends the life of the product. AkyPak®’s closed edge enhancement is engineered to withstand the challenges of heavy use and exposure to various handling processes.

Designed with easy maintenance in mind, the closed edges also simplify cleaning. Whether using a quick brush, damp cloth, or spray, the design supports efficient maintenance routines, avoiding water penetrating the fluting and helping to uphold hygiene standards.

The hygienic, safe and durable nature of the technology makes it ideal for the pharmaceutical market, while in food its easy-to-clean design also adheres to hygiene standards. Applications, such as fresh fish, are aided from the sealed edges which combat contamination. Additionally, the automotive and electronics sectors benefit from AkyPak®’s robust structure.

“Closed edge technology pushes AkyPak® into new territory,” said Corplex CEO Lucas van der Schalk. “It reinforces the primary function of packaging – to protect the product – in a durable, hygienic and sustainable solution. With reusability built in, AkyPak® goes a long way to help customers reduce their impact on the environment.”

Usability is another factor in the innovation, with closed edges ensuring handling and assembly is simple. Snap flaps and tabs allow users to assemble and disassemble packs with ease, saving time in settings that demand swift packaging solutions such as cosmetics or electronics industries. In addition, closed edges offer a less abrasive edge for operators in industries that involve extensive manual interaction with packaging.

“For all the practical benefits of closed edge technology for AkyPak®, there is an additional factor, aesthetics,” added Lucas van der Schalk. “The new packs offer a refined, professional finish in high visibility settings like retail, cosmetics and pharma. It allows brands to stand out on shelf in fiercely competitive markets.”

AkyPak®, made from Correx®, has a wide range of products on offer. From reusable boxes to foldable containers, the solutions are tailored to every market’s unique robust packaging needs.

Related News