Users Mayfield Press and Pip n Chip – two very different companies – highlight how their swissQprint machines have grown with their business needs

Two companies, who are established users of swissQprint machines, have been learning how their large format printers are made to be futureproof. Their modular design enables users to add colour channels and options as needed, meaning a business’ growth can be matched by its swissQprint machine.

Upgradable In the field

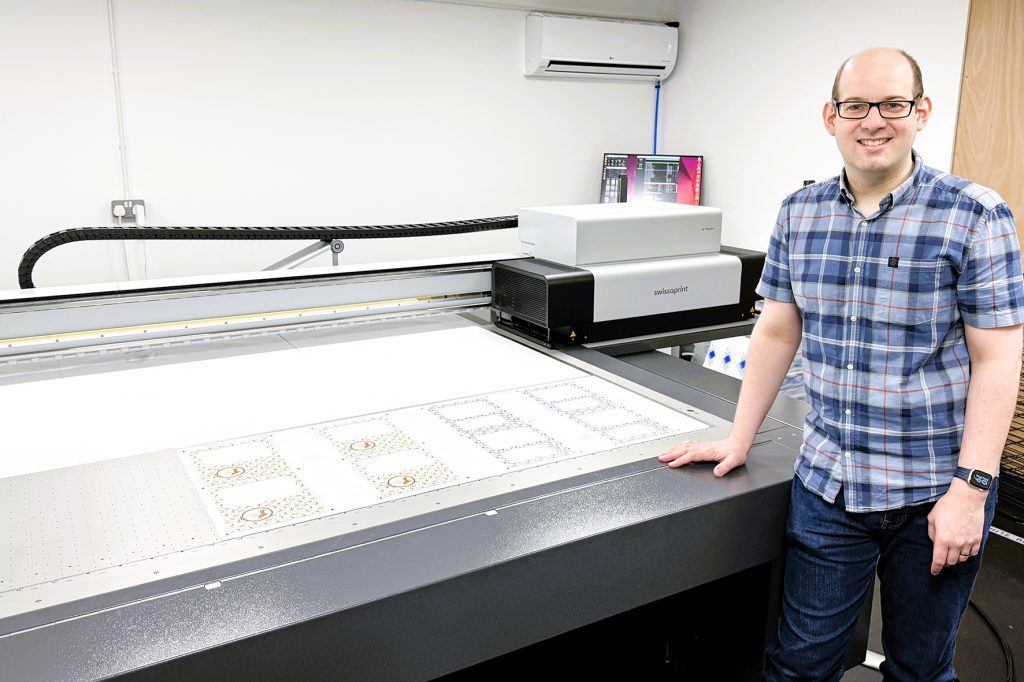

In 2018, Oxford-based digital and lithographic printer Mayfield Press, was first introduced to a swissQprint machine after it captured the team’s attention during a supplier’s factory tour. After this, arrangements were made to see a Nyala 3 in action and, impressed by its remarkable efficiency and print quality, Mayfield Press instantly made the purchase.

“As soon as we saw it, we could tell it was going to be worth it, and it made an immediate impact on our business,” said Dan Warner, Head of Operations at Mayfield Press.

Three years later, Mayfield Press was tasked with a large braille signage project for Microsoft. Rather than outsourcing the work, the team saw it as the perfect opportunity to upgrade its Nyala with an additional channel for varnish applications. swissQprint’s engineers completed the upgrade in less than a day, minimising the downtime before the braille application could be fully printed in-house.

Adding value with varnish

Since then, the ability to print varnish has unlocked several further signage and wayfinding opportunities. The upgraded Nyala has also expanded Mayfield’s service offerings, with spot varnish applications and texture printing playing an increasingly important role in its design solutions. In addition, swissQprint’s droptix 3D effect technology has accelerated the business’ creative work, with samples showcasing the machine’s capabilities.

Dan concluded, “We can now offer our clients so much more. This upgrade has helped us achieve new heights and has seen the Nyala grow with the needs of our business.”

A week’s work in a single day

Pip n Chip, a manufacturer of bobbin pins for cross-stitching, purchased its second-hand Impala 3 in November 2023 and chose to add an orange colour channel as part of the installation. To meet its needs of matching hundreds of spot colours, the orange ink significantly increased the machine’s colour gamut to deliver the precision customers required.

Since installation, the Impala has revolutionised Pip n Chip’s operations, enabling the team to complete a week’s worth of production in a single day! The growing business is now exploring a roll to roll option as a further upgrade to make greater use of the machine’s application versatility.

“The Impala has had a dramatic impact on our production. We are delighted with its precision, reliability, and overall performance,” said Director Craig Wanstall. “Purchasing a second-hand printer may have been seen as a risk, but the Swiss build quality is clear to see. This, combined with its ability to grow around our needs, has made the Impala the perfect machine for our business.”

A futureproofed, sustainable investment

Machine longevity is a key part of swissQprint’s strategy. Commenting on the upgrades, Erskine Stewart, UK Managing Director of swissQprint said, “swissQprint machines have sustainability built into their core as both Mayfield Press and Pip n Chip have confirmed. Their robust and modular nature ensures they not only grow alongside businesses but continue to open new opportunities many years after their installation.”