The event graphics provider has moved to a new facility and installed a Mimaki flatbed and JWEI cutter to increase in-house efficiency.

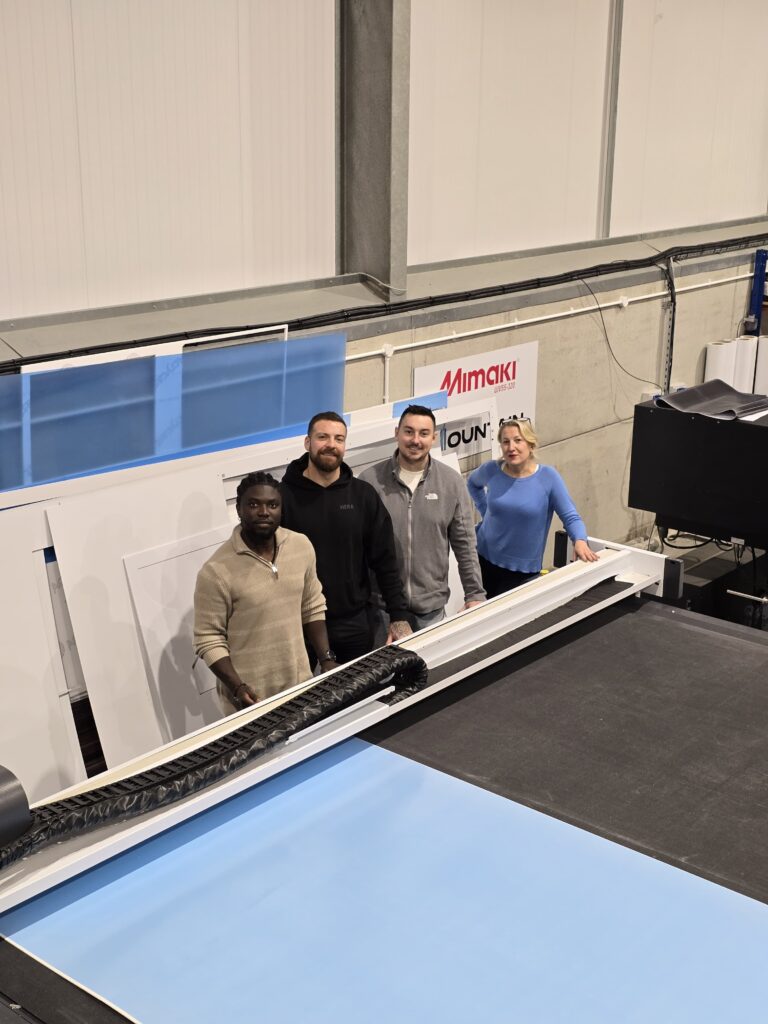

Event graphics provider, Mountain Print, has invested in a new Mimaki JFX500-2131 UV LED flatbed printer and a JWEI JCUT-3230 digital cutting table from CMYUK. This upgrade coincides with the company’s move to a new 6,000 sq. ft facility, a strategic step intended to support further growth and expanded capabilities.

Darrell Mountain, company owner, commented on the recent changes, “This year has been record-breaking for us on print with the onboarding of several new clients. We recognised the necessity of expanding our in-house services to meet tighter deadlines and ensure quality control. This latest investment allows work us to better service our clients and maintain the high standards they expect without being forced to outsource work.”

The relocation to a larger production facility is designed to improve production flow. “With the majority of our work based in London along with our partnerships with various London venues, relocation has allowed us to be more responsive for last minute requests,” Mountain explains.

Mimaki JFX500-2131 investment

The decision to invest in the Mimaki JFX500-2131 was driven by the company’s previous experience with the manufacturer’s technology. “We greatly appreciate the quality and reliability of our existing Mimaki UJV55-320 roll-to-roll UV LED printers, which have been nothing short of incredible. This positive experience motivated us to further invest in the dedicated flatbed printer. Our production team are very familiar with Mimaki operations, so it made perfect sense,” says Mountain.

According to Mountain, the ability to print with white ink is a significant addition to their service offering. “The output of what we can do from the new printer is incredible. The white ink has just enhanced capabilities in-house for our clients, which we’ve never had before. Previously any white ink jobs had to be outsourced but now we can handle everything internally, saving time and money,” Mountain notes.

To address finishing requirements, the company selected the JWEI JCUT-3230. Mountain highlights the efficiency gains from the new system. “We’ve saved 80% of labour just by transitioning to the flatbed, printing direct to substrate and then cutting. Previously, we were printing to vinyl, applying it to board, and then cutting.”

“The JWEI partners really well with our 3.2m wide printers. We do lots of Silicon Edge Graphics (SEG) here. We put our printed textiles straight onto the JWEI where they are cut quickly and accurately, and then we finish them in-house. The time saving is immense,” explains Mountain.

The JWEI system handles various applications, including card printing, custom boxes, sign trays, and acrylic processing. “There’s nothing we produce that doesn’t go through the JWEI, it’s so versatile. Our six printers can’t keep up with the workflow that the JWEI can get through. It’s an absolute ravenous beast, it’s really quick, and just so good,” says Mountain.

Mountain Print also cited the support from CMYUK as a factor in the investment success. With the new facility and equipment in place, the company aims to continue its growth trajectory. “There’s nothing we can’t do in-house now. The next thing would possibly be a wider printer, bringing in another level of service and opportunity,” concludes Mountain.